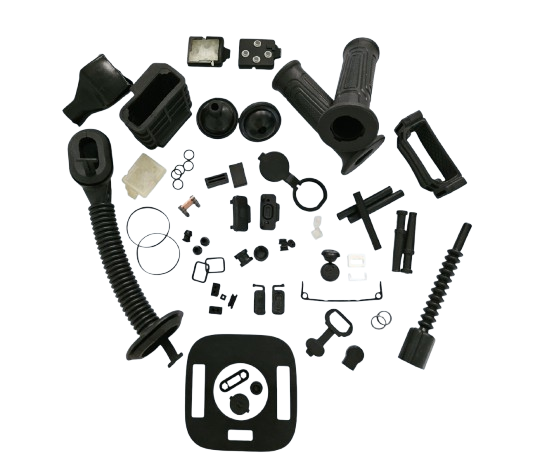

Other Engineering Elastomeric Components

We offer a diverse range of customized elastomer products designed to meet the specific needs of customers. Our experience includes silicone elastomers, known for their high-temperature resistance and flexibility, making them ideal for automotive gaskets, seal. EPDM (Ethylene Propylene Diene Monomer) is another key offering, valued for its excellent weather resistance, perfect for automotive weather seals and other parts. Nitrile rubber (NBR) provides strong resistance to oils and chemicals, making it suitable for fuel hoses and O-rings. Our polyurethane elastomers feature high abrasion resistance and durability, ideal for wheels, seals, and cushioning materials in industrial applications. Our thermoplastic elastomers (TPE) combine the benefits of rubber and plastic, providing versatility and recyclability for consumer goods and automotive parts. With a commitment to innovation and quality, our team ensures that each customized elastomer solution enhances the performance and reliability of your products.

Manufacturing Processes

Our elastomer products are produced using a variety of advanced manufacturing techniques, including:

Compression Moulding

Ideal for producing large quantities of parts with complex shapes, typically used for producing seals, gaskets, and automotive components.

Transfer Moulding

Offers flexibility in producing precise and high-quality parts, often used for applications where tight tolerances are required.

Injection Moulding

Commonly used to create highly detailed and intricate elastomer components in high-volume production runs.

Extrusion

Suitable for continuous production of elastomeric profiles such as seals, tubing, and gaskets.

Types of Components

We specialize in manufacturing a wide variety of elastomer components tailored to the specific needs of our customers:

Grommets

Boots

Bellows

Tubes

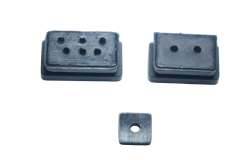

Dampers

Metal to rubber bonded components

Sealants

O-rings

Washers

Handlebar grips

C-type USB charger caps

Key Features of Our Elastomer Products

- Our elastomer solutions are engineered with several key properties that enhance their performance and suitability for demanding environments.

- High Ozone Resistance: Our materials are specially formulated to resist degradation from exposure to ozone, ensuring durability in outdoor and automotive applications.

- High and Low Temperature Withstand ability: Our elastomers can perform across a broad temperature range, making them suitable for both high-temperature environments and freezing conditions.

- High Abrasion Resistance: Many of our elastomer materials are designed to resist wear from friction, ensuring longevity in applications such as seals and industrial parts.

- Good Electrical and Mechanical Properties: Our elastomers offer excellent insulation and mechanical strength, making them ideal for components requiring both electrical safety and physical durability.

- With a strong commitment to innovation and quality, our team ensures that each customized elastomer solution not only meets but exceeds the performance and reliability standards required for your products. By leveraging advanced technology and expert knowledge, we deliver elastomer components that enhance the efficiency, safety, and longevity of your applications, providing solutions that are tailored to the evolving demands of industries ranging from automotive and electronics to industrial and consumer goods.